MTU Mercedes-Benz Series Diesel Generator Set

Product feature

1. Easy maintenance: Water-cooled four-stroke, 90°V cylinder arrangement, turbocharged intercooling, wet replaceable cylinder liner, one cylinder and one cap, dry exhaust manifold, easy maintenance.

2. Intelligent operation: The special ADEC electronic management system CAN provide accurate digital electronic speed regulation function, set data collection points at key parts of the fuselage, it can achieve fault self-diagnosis and automatic display, intelligent unit operation, CAN bus technology. (Type 4000: When the load is low, the unit automatically transfers to the half-cylinder working state.).

3. High operating reliability: Apply 3 gas ring aluminum alloy piston structure, uses wear-resistant cast iron and valve seat insert ring structure in the top ring of the piston to extend the service life, piston oil injection cooling system can effectively solve the cooling and heat dissipation, so the unit operation is more reliable.

4. Energy saving and environmental protection: Apply unique electronic control monomer fuel injection pump, together with direct injection in the cylinder, so the emission is better than the German TA Luft standard, electronic intelligent management has lower fuel consumption, it is the first one to break the bottleneck of 200g/KWh. (Type 4000: The first one to use advanced common rail injection technology, under the precise control of the electronic management system, the injection is more accurate, the combustion is more full, and the fuel consumption is lower).

5. Excellent performance: Stable operation, small vibration, low fuel consumption rate, low oil consumption rate, long operating life, low noise.

MTU Mercedes-Benz Series

|

Unit Type |

Unit power KW |

Diesel type |

Spare Power |

Number of cylinders | Cylinder diameter/stroke

(mm) |

Unit Dimension Length*width*Height mm |

Unit Weight KG |

Emisson Standard |

|

|

Main |

Spare |

||||||||

|

GD220GF |

220 |

240 |

6R1600G10F |

274KW |

6 |

122*150 |

2615*1090*1380 |

2100 |

III |

|

GD250GF |

250 |

275 |

6R1600G20F |

303KW |

6 |

122*150 |

2650*1100*1380 |

2250 |

III |

|

GD300GF |

300 |

330 |

8V1600G10F |

358KW |

8 |

122*150 |

2750*1100*1450 |

2500 |

III |

|

GD320GF |

320 |

350 |

8V1600G20F |

394KW |

8 |

122*150 |

2950*1385*1590 |

2730 |

III |

|

GD360GF |

360 |

400 |

10V1600G10F |

448KW |

10 |

122*150 |

3260*1500*1940 |

3030 |

III |

|

GD400GF |

400 |

440 |

10V1600G20F |

493KW |

10 |

122*150 |

3065*1580*1995 |

3170 |

III |

|

GD480GF |

480 |

520 |

12V1600G10F |

576KW |

12 |

122*150 |

3170*1760*1995 |

3420 |

III |

|

GD520GF |

520 |

570 |

12V1600G20F |

634KW |

12 |

122*150 |

3890*1630*1950 |

5200 |

III |

|

GD556GF |

556 |

610 |

12V2000G25 |

695KW |

12 |

130*150 |

3890*1630*1950 |

5460 |

III |

|

GD630GF |

630 |

700 |

12V2000G65 |

765KW |

12 |

130*150 |

4330*1770*1950 |

6150 |

III |

|

GD730GF |

730 |

800 |

16V2000G25 |

890KW |

16 |

130*150 |

4368*1770*2322 |

6250 |

III |

|

GD800GF |

800 |

880 |

16V2000G65 |

979KW |

16 |

130*150 |

4570*2020*2210 |

7160 |

III |

|

GD910GF |

910 |

1000 |

18V2000G65 |

1100KW |

18 |

130*150 |

4650*2020*2210 |

7500 |

III |

|

GD1000GF |

1000 |

1100 |

18V2000G26F |

1212KW |

18 |

130*150 |

4700*2020*2300 |

8000 |

III |

|

GD1100GF |

1000 |

1100 |

12V4000G23R |

1205KW |

12 |

170*210 |

5220*2085*2300 |

10600 |

III |

|

GD1320GF |

1240 |

1320 |

12V4000G23 |

1575KW |

12 |

170*210 |

5320*2085*2755 |

10860 |

III |

|

GD1450GF |

1450 |

1600 |

12V4000G63 |

1750KW |

12 |

170*210 |

5775*2415*2905 |

13450 |

III |

|

GD1600GF |

1600 |

1760 |

16V4000G23 |

1965KW |

16 |

170*210 |

6080*2580*3045 |

14185 |

III |

|

GD1800GF |

1800 |

2000 |

16V4000G63 |

2162KW |

16 |

170*210 |

6080*2580*3045 |

14185 |

III |

|

GD2000GF |

2000 |

2200 |

20V4000G23 |

2420KW |

20 |

170*210 |

6000*2200*2500 |

17500 |

III |

|

GD2200GF |

2200 |

2400 |

20V4000G63 |

2670KW |

20 |

170*210 |

6000*2200*2500 |

18000 |

III |

|

GD2400GF |

2400 |

2600 |

20V4000G63L |

2850KW |

20 |

170*210 |

6000*2250*2500 |

19500 |

III |

Product details

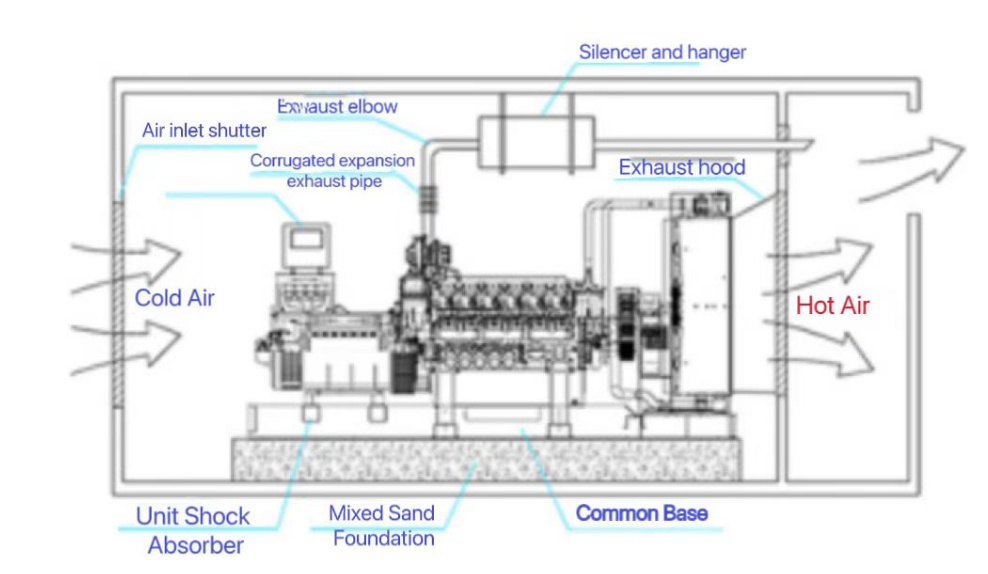

(1) Installation is as simple as you like.

Heavy concrete foundations that do not require the use of reducing bags.

It only needs to be mounted on a concrete slab that can support its weight.

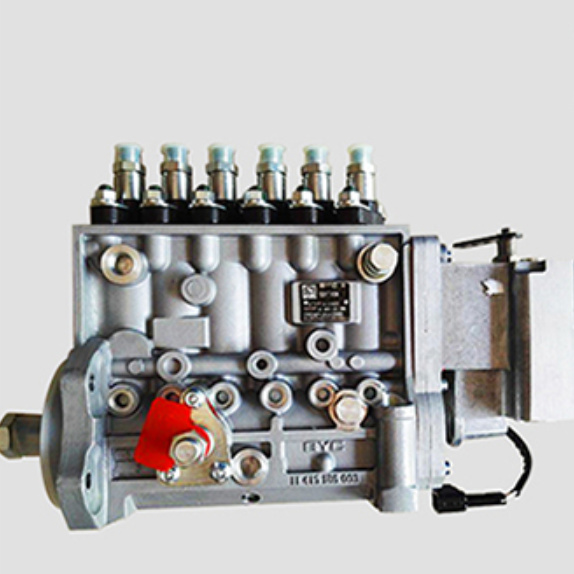

(2) Electrically regulated high-pressure fuel injection pump: more stable, more fuel efficient, more simple automatic adjustment of the throttle according to the size of the load, making the current and voltage stable, improving the stability of the unit operation, the throttle is more accurate, diesel combustion is efficient, eliminating the tedious manual adjustment of personnel.

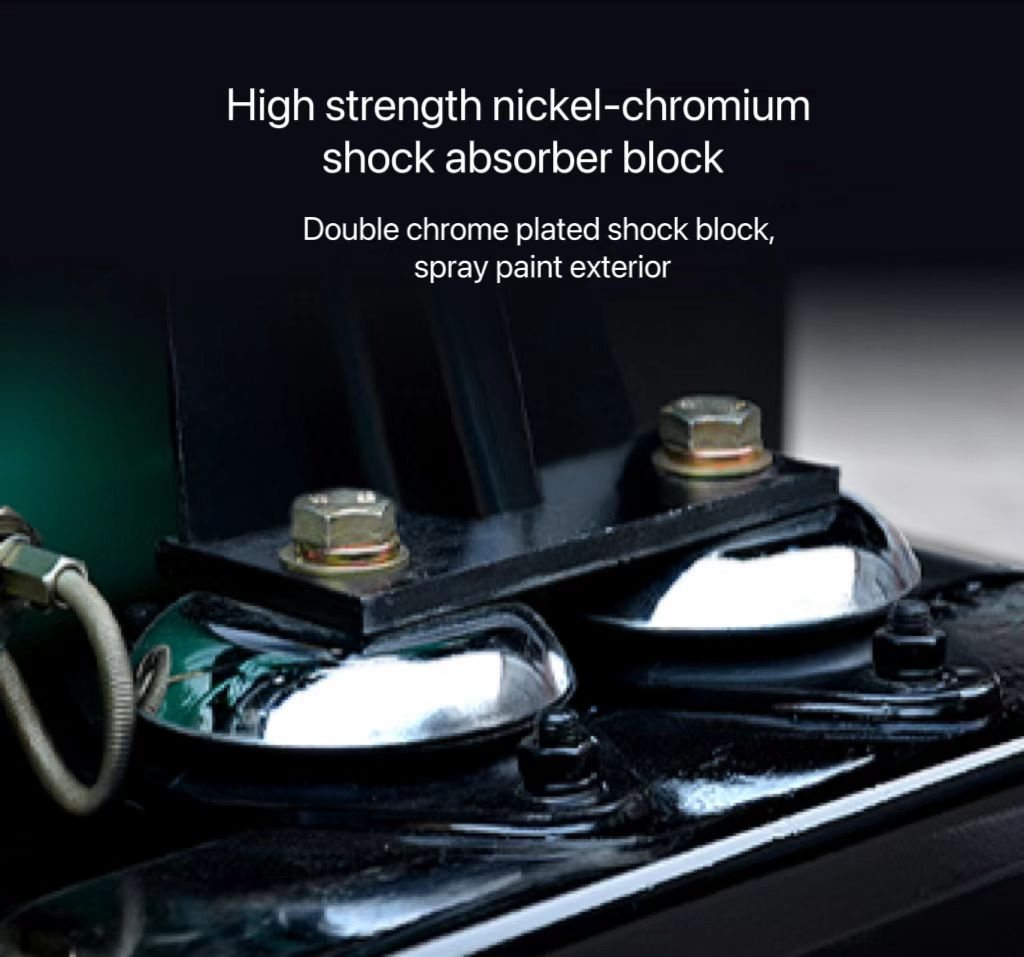

(3). 5MK Thickened board spray paint surface, height is 20cm.

High strength bending base frame.

(4)

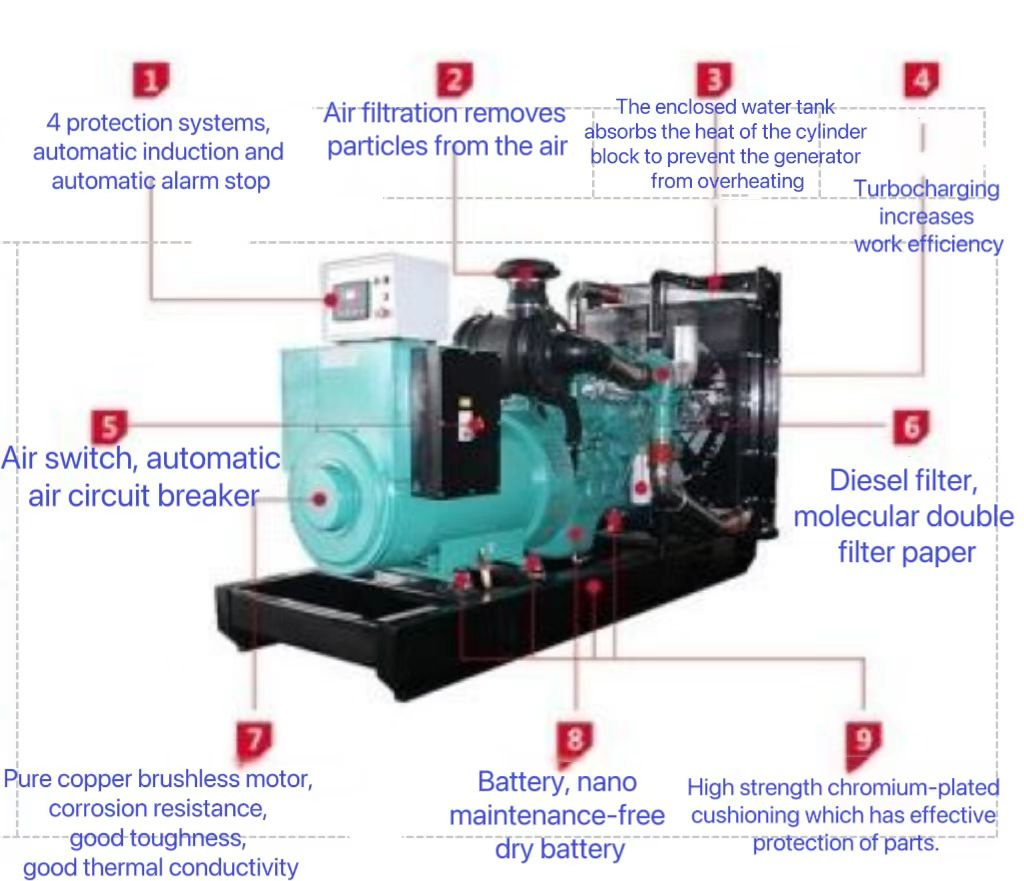

(5) All copper brushless motor

Power enough, high temperature resistance all copper wire, low loss, power enough

The output is stable, the motor core length is long, the diameter is large

Maintenance-free, eliminating conductive carbon brushes in brushed motors

Low noise, running voltage is very stable, long life, low noise

High precision, suitable for some high-precision equipment and electrical equipment use

(6)

Packaging Details: Genaral wrap film packaging or wooden case or according to your requirements.

Delivery Detail: Shipped in 10 working days after payment.

Warranty period: 1 year or 1000 running hours whichever comes first.